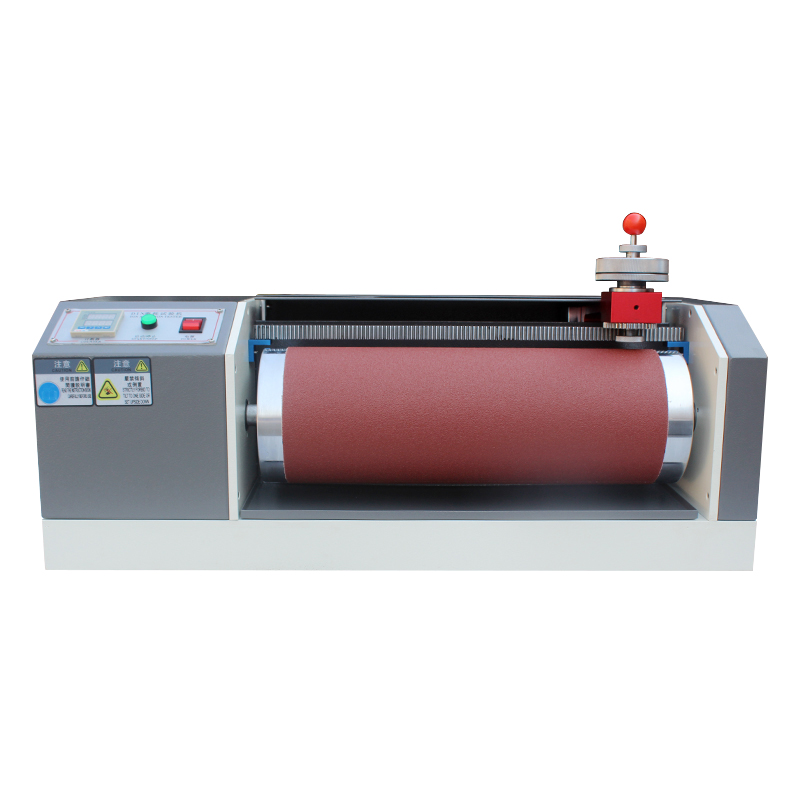

DIN-53516 ISO/DIS-4649 Abrader Rubber DIN Abrasion Tester Manufacturer

Application

This abrasion tester is said to allow users to measure the abrasion resistance of rubbers (vulcanized thermoset rubbers and thermoplastic elastomers) that are subject to abrasive/frictional wear in their actual service, such as tires, conveyor drive belts and shoe soles. Since wear is always a result of abrasion, different test methods have been developed for the simulation of long term wear. The method conforming to ASTM D5963/ ISO 4649 has proven to be the best way of simulating long term wear, according to the company.

Standards

DIN-53516,ISO/DIS-4649,GB-9867

Principle

Under a predetermined contact pressure and a given area,the specimen with sandpaper angled to measure abrasion resistance of the specimen subjected to rubbing on a certain level of sandpaper, sandpaper affixed to the surface of the drum, samples pressed on a drum with sandpaper, and the specimen along the roller to the lateral movement, abrasion resistance is produced at one end of the cylindrical specimen, tests the value of the mass loss of the specimen, by the density of the specimen to calculate the amount of volume abrasion.

Specifications

Roller diameter:φ150mm

Roller length:460mm

Rotate speed:40rpm

Abrasion stroke:40mm(20mm)

Abrasion speed:0.32m/sec

Dip angle:3°

Specimen diameter:φ16 mm

Thickness:6~15 mm

Testing load:5N,10N

Clamp horizontal displacement:4.2mm/roll each lap

Standard accessories:one set of sampler,two pieces of abrasive

paper(VSM60#,41*47.6CM),three pieces of standard gel(φ16*8mm),one piece of power cord.

English

English