Leeb Hardness Tester for Metal Steel Electric Leeb Hardness Tester for Metal Steel

Digital Leeb hardness tester is developed Leeb hardness measurement principle based on the internationally popular metal material hardness tester. It has high accuracy, small size, easy to operate, and a wide range of measurement, especially for large, heavy-duty malleable pieces, example: roll turbine shaft, and applied to the components already installed and can not be demolished, for example, site hardness testing of pressure vessels, turbine units and other equipment. Leeb hardness tester is widely used in petrochemical, aerospace, electric power, gas, automotive, shipbuilding, railways, machinery manufacturing and other industries.

TECHNICAL DATA

Measuring Materials | Steel and cast steel, alloy tool steel, stainless steel, gray cast iron, nodular cast iron, cast aluminum alloy, copper zinc alloys (brass), copper and tin alloy, copper (bronze), forged steel |

Measuring Range | HLD(170~960), HRC(17.9~69.5), HB(19~683), HV(80~1042), HS(30.6~102.6), HRA(59.1~88), HRB(13.5~101.7) |

Indication Error | ±6HLD (D impact device) |

Measuring Direction | 360° |

Hardness Scale | HL, HB, HRB, HRC, HRA, HV, HS |

Display | 128*64 digital matrix LCD |

Data Memory | Max 600 groups (relative to impact times 1~32 adjustable) |

Power | Rechargeable li-battery |

Working Temperature | -20°C~55°C |

Size | 210x85x45mm |

Weight | 0.6kg |

MAIN FEATURE

*Built-in printer, can print testing results any time;

*Test at any angle, even upside down;

*Has a starting value calibration function, ensure the data is applicable and accurate in different codes and standards;

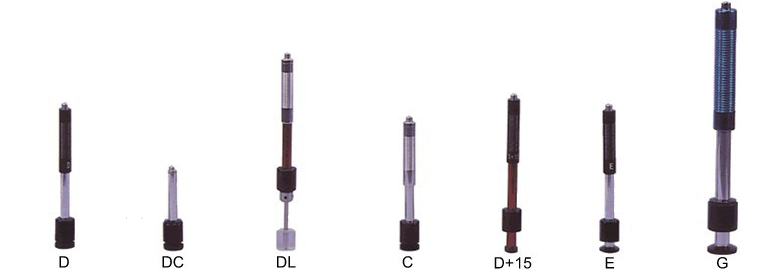

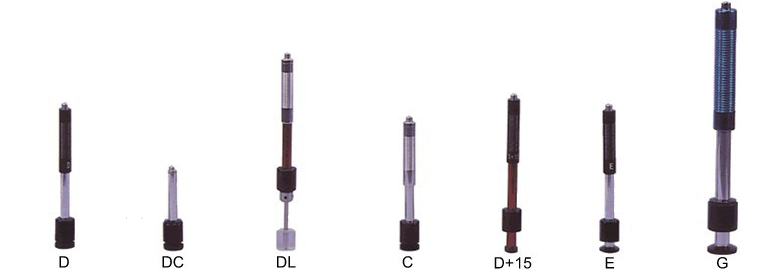

*Seven impact devices are available for special application. Automatically identify the type of impact devices;

*User calibration function;

*Battery information indicates the rest capacity of the battery and the charge status;

*Has the function of automatic alarm. Pre-set tolerance limit, beyond the range has automatic alarm, especially suitable for batch testing;

*Menu operation, information rich, intuitive, the realization of arbitrary switching material and hardness of system's key type, simple and convenient;

*Excellent after-sale service system for high quality products-two years warranty and all life maintenance. Easy to operate;

*Narrow space also available to use;

*Support OEM Service;

*High price performance.

STANDARD DELIVERY

ITEM | QTY |

KH520 Host | 1 PC |

Standard D Impact Device | 1 PC |

Standard Calibration Block | 1 PC |

Standard Support Ring | 1 PC |

Brush | 1 PC |

USB Cable | 1 PC |

PC Software | 1 PC |

User Manual | 1 PC |

Instrument Case | 1 PC |

Warranty | 2 Years |

RELATED OPTIONAL ITEMS

RELATED OPTIONAL ITEMS

Type of Impact Device | DC(D)/DL | D+15 | C | G | E |

Impacting energy Mass of impact body | 11mJ 5.5g/7.2g | 11mJ 7.8g | 2.7mJ 3.0g | 90mJ 20.0g | 11mJ 5.5g |

Test tip hardness: Dia. Test tip: Material of test tip: | 1600HV 3mm Tungsten carbide | 1600HV 3mm Tungsten carbide | 1600HV 3mm Tungsten carbide | 1600HV 5mm Tungsten carbide | 5000HV 3mm synthetic diamond |

Impact device diameter: Impact device length: Impact device weight: | 20mm 86(147)/75mm 50g | 20mm 162mm 80g | 20mm 141mm 75g | 30mm 254mm 250g | 20mm 155mm 80g |

Max. hardness of sample | 940HV | 940HV | 1000HV | 650HB | 1200HV |

Mean roughness value of sample surface Ra: | 1.6μm | 1.6μm | 0.4μm | 6.3μm | 1.6μm |

Min. weight of sample: Measure directly with stand Need coupling tightly | >5kg 2~5kg 0.05~2kg | >5kg 2~5kg 0.05~2kg | >1.5kg 0.5~1.5kg 0.02~0.5kg | >15kg 5~15kg 0.5~5kg | >5kg 2~5kg 0.05~2kg |

Min. thickness of sample Coupling tightly: Min. layer thickness for surface hardening: | 5mm ≥0.8mm | 5mm ≥0.8mm | 1mm ≥0.2mm | 10mm ≥1.2mm | 5mm ≥0.8mm |

Size of tip indentation |

Hardness 300HV | Indentation diameter: Depth of indentation: | 0.54mm 24μm | 0.54mm 24μm | 0.38mm 12μm | 1.03mm 53μm | 0.54mm 24μm |

Hardness 600HV | Indentation diameter: Depth of indentation | 0.54mm 17μm | 0.54mm 17μm | 0.32mm 8μm | 0.90mm 41μm | 0.54mm 17μm |

Hardness 800HV | Indentation diameter: Depth of indentation | 0.35mm 10μm | 0.35mm 10μm | 0.35mm 7μm | -- -- | 0.35mm 10μm |

Application | DC type used to measuring hole or inside face of cylinder, DL type used to measuring elongated narrow slot or hole, D type for routine measurements. | Suitable for measuring surface of the trench or concave. | Suitable for measuring thin workpiece and harden surface. | Suitable for heavy or rough castings and forgings. | Suitable high hardness material. |

English

English